COLD STORE OF NEW GENERATION FOR CARROTS STORAGE

MIZERA G.(*), BURTYMOWICZ D.(*)

(*) Institute of Fluid-Flow Machinery Polish Academy of Sciences, Fiszera 14, Gdansk, 80-952, Poland

gmizera@imp.gda.pl

ABSTRACT

The paper presents the new generation of vegetable cold-storage equipped with the indirect refrigeration system and using the air coolers with the capacity regulation. In place of traditional on/off thermostat (located in the inlet air to the air cooler), the analogue thermostat (with capacity regulation) is applied in the outlet air from air cooler. The control system is based on the three-ways valve with the motor controlled by the analogue thermostat. The applied control system keeps the coolant temperature at the level which is required for the unsteady heat load of the air-cooler. The cold store has capacity of 10 000 tons of carrots and is used for a long-time storage. This cold-storage fulfils the requirements of the modern refrigeration technology: reduction of the refrigerant charge in the system, condensation heat recovery to defrost the aircooler and to heat the social-rooms, plastic piping, application of computerised system for control and supervising, and unification of the applied technical solutions. The technological benefits in terms of quality of stored carrots due to applied capacity regulation approach have been also discussed in the paper.

1. INTRODUCTION

In Poland carrots are one of the most popular vegetables. Poles eat about 21 kg of carrots per person per year which is about 15% of the total consumption of vegetables in Poland. They are grown on the area of about 30 000 ha with a harvest of about 800 000 tons per year. Most of the carrots are collected in late autumn. The consumption is virtually the whole year until the next harvest with a particularly high consumption during the winter and spring season. Therefore, there is a natural gap between the harvesting time and the period of consumption. So, there is a need for a long-term storage of harvested carrots.

A prerequisite for good storage of carrots is to keep them at temperature close to cryoscopic temperature (but not lowering to much under threat of destruction of stored carrots.) At these temperatures the life processes of carrots are slowed what influences the process of ageing. Another important factor affecting the quality of carrots is humidity in the chamber. Since only 12% of the carrots form so-called dry substance and the rest is water, carrots lose moisture very easy if they are kept in air of too low humidity (Adamicki, 2002, 2006).

Therefore, the best conditions for long-term storage of fresh carrots can be created by keeping them in the cold storage.

The main requirement for cold storage of carrots is to have the necessary cooling capacity that ensures quick cooling of the daily load of fresh carrots supplied from a field. Quick cooling of harvested carrots reduces the intensity of respiration process, and the development and spread of all pathogens. The cooling system should guarantee the same temperature and high humidity of stored carrots in the entire volume of the storage chamber. Humidity should be kept near saturation point but without condensation of moisture on the stored carrots. The moisture condensing on the carrots is the cause of their decay. All of these technological requirements should be implemented simultaneously with the other technical requirements for modern refrigeration systems.

2. COOLING SYSTEM FOR LARGE COLD STORES OF CARROTS

The above discussed requirements have influence on design, construction and operation of the cold storage chambers as well as the impact on the environment. The technical solution shown here (10 000 tons carrots cold storage) is a practical attempt to fulfil all of these requirements. In order to meet the technological requirements refrigeration system has been equipped with the air coolers of controlled capacity.

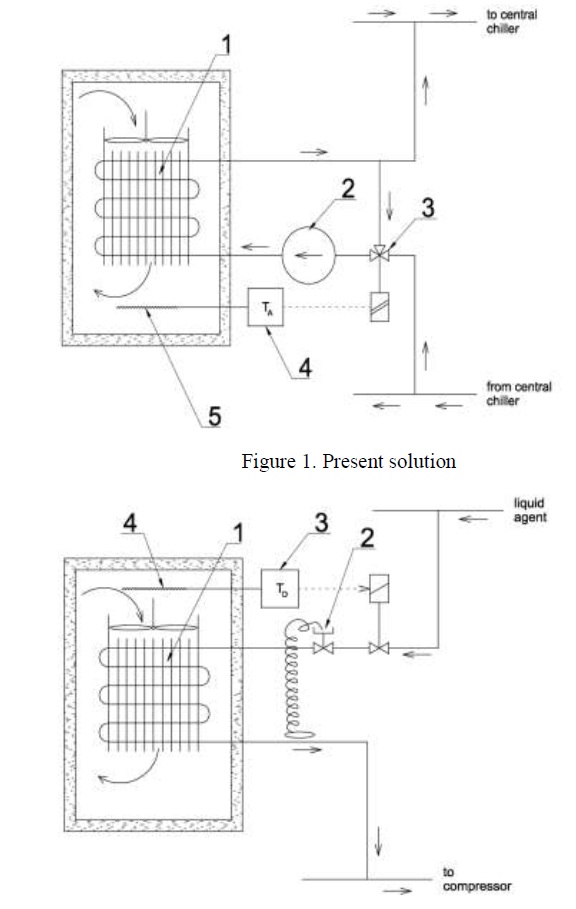

The typical cooling system arrangement is shown in Figure 1. This system (with intermediate coolant, here with propylene glycol) is composed of lamella air cooler with fan (1), circulation pump (2), three-ways valve (3) and analogue thermostat (4) controlling the temperature of the air by means of the sensor (5). This system is powered by the coolant flowing from the central chiller. Adjusting of the air cooler efficiency is done by adjusting the temperature of the coolant in the air cooler to the instantaneous heat load through a mixing valve. Note, that the period of the chamber restocking (and additional heat load from working forklifts and doors opening) takes only few days and it may be treated as negligible in comparison with the total storage time (6-8 months). However, even under these conditions the presented solution shows the advantages. It holds the air temperature at a constant level regardless of the instantaneous heat load. Increase the heat load of the air cooler changes the opening of the three-ways valve and lowering the temperature of the coolant flowing through the air cooler. The process continues until the balance between heat load and the capacity of air cooler will occurs. When the heat load is higher than capacity of the air cooler with fully open valve then its capacity further increases by lowering the temperature of the coolant leaving the chiller. This system replaces the commonly used traditional, standard solution presented in Figure 2.

Figure 2. Typical solution

Figure 2. Typical solution

The solution presented in Figure 2 consists of a lamella air cooler with fan (1), expansion valve (2) and a conventional thermostat (3) (ON / OFF) with the sensor (4) positioned in the air flowing into the air cooler.

This solution guaranties stable temperatures of air at the inlet and outlet to the air cooler as well as ensures the lowest acceptable air temperature.

The presented new system allows the cooling capacity adjustment of the air cooler to the instantaneous cooling demands. The main disadvantage of the direct expansion system is the problem of keeping stable superheating of refrigerant vapour leaving the evaporator. The standard level of the superheating for thermostatic valves is 4 – 6 K at minimum. Because circulated air is a source of the heat then air temperature should be higher than temperature of vapour leaving the air cooler. As a result the temperature difference between evaporation and circulated air must be higher than superheating temperature difference.

This causes dehumidification of air in the storage chamber as well as dehydration of stored vegetables. The refrigeration system operates with maximum capacity only during period of loading of fresh carrots. After this period (lasting about two weeks) the cooling capacity drops significantly reaching a minimum stable value during the storage season (lasting few months).

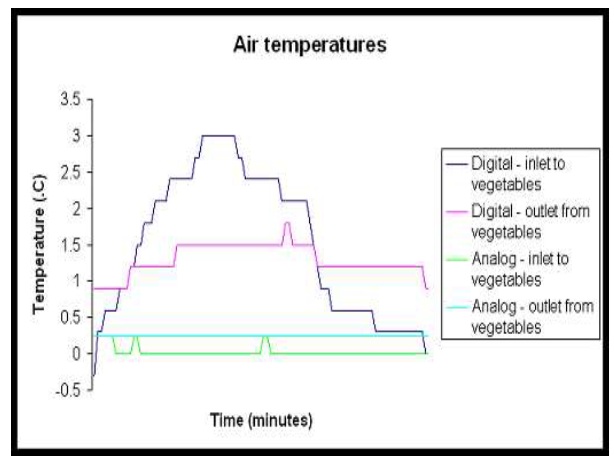

Figure 3. Comparison of air temperatures in present and typical solutions.

Figure 3. Comparison of air temperatures in present and typical solutions.

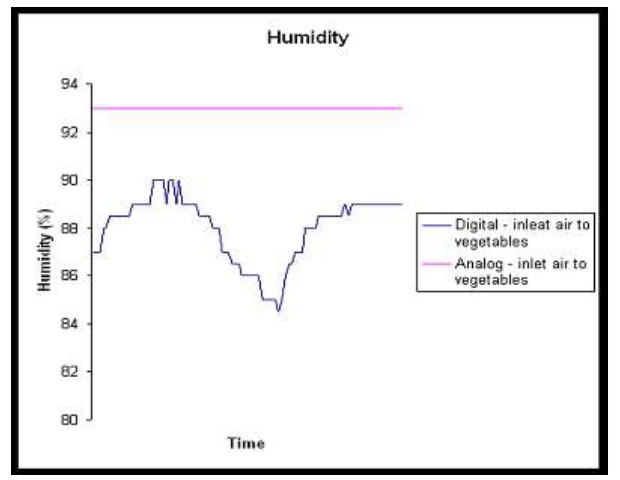

Figure 4. Comparison of air humidity in present and typical solutions

Figure 4. Comparison of air humidity in present and typical solutions

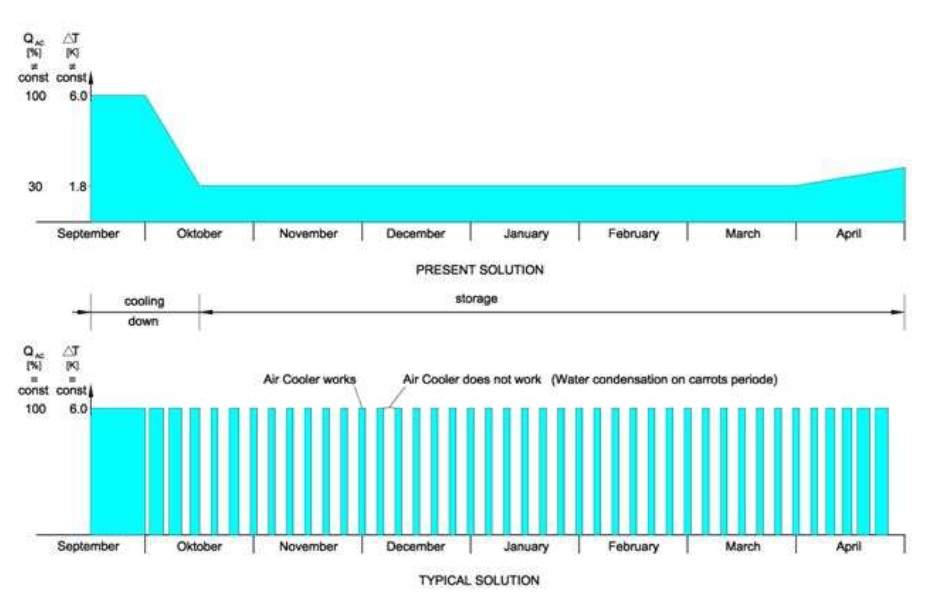

Figure 5. Comparison of work air cooler during storage season in present and typical solutions.

Figure 5. Comparison of work air cooler during storage season in present and typical solutions.

3. EVALUATION OF OPERATION OF PROTOYPE LARGE COLD STORE OF CARROTS

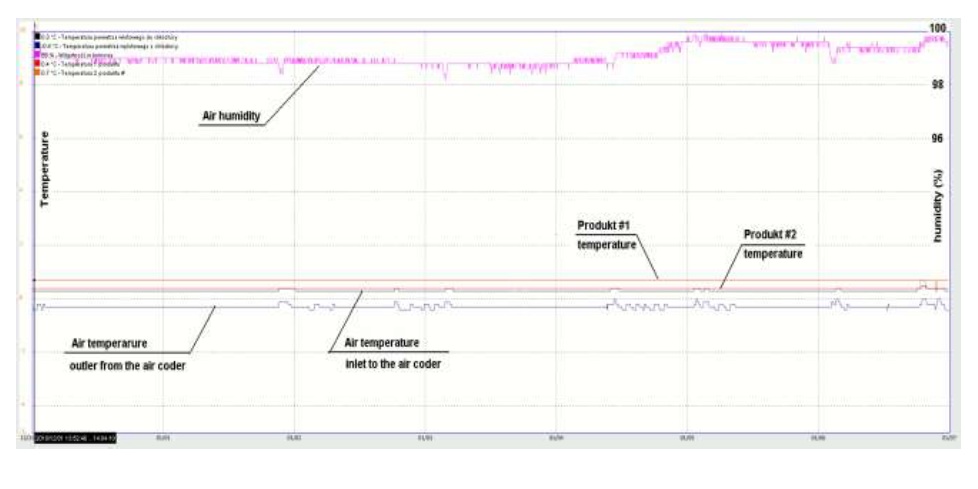

The use of the air cooler with adjustable capacity allows to work with very little temperature difference in temperatures between air temperature in the cold chamber and the coolant. This assures very high humidity level in the cold storage chamber. Direct expansion systems are often designed for quick cooling during loading of fresh carrots. In the winter they work 20 – 30% of the time only. In spite of the investment costs the remaining time (70-80% time) they do not work. Comparison of the stability of air temperatures at the inlet and outlet of air coolers for the presented and typical systems is presented in Figure 3 and comparison of humidity is shown in Figure 4. The problem of condensation of moisture on stored carrots is very important because of the accompanying decay and the associated qualitative and quantitative losses in stored carrots. In traditional systems the air cooler is the coldest element in the chamber. When the air temperature set up by the thermostat is achieved the air cooler is off. Then carrots became the coldest element in the chamber. This way the moisture will be condensed on carrots. Therefore, the source of these problems is not high level of humidity but the cyclic operation of the air cooler. Comparison of work air cooler during storage season in present and typical solution is presented in Figure 5. In solution with the adjustable capacity of the air cooler such phenomena do not occur. This new solution increases the work rate of the installed air coolers, improves temperature stability throughout the chamber and increases the relative humidity in the chamber as well as prevents the condensation process of moisture on the stored carrots. Apart from technological advantages of having the impact on the quality of carrots after the storage, this new system fulfils the technical demands and environmental challenges for modern refrigeration systems. The described system reduces the amount of refrigerant charge (R 404A) since refrigerant is charged only in the chiller. The chiller has been produced in special workshop with guarantee of high quality and reliability. The use of heat recovery from superheated vapour of R 404A allows defrosting of the air coolers. This solution simplifies electrical installation (no dedicated heaters, electrical cables, electrical cabinets, etc.) and saves energy. In contrast with coolant piping, the refrigerant piping works at high pressure and should guarantee proper oil circulation. Refrigerant pipeline should be designed, constructed and maintained by experienced contractors. In carrots cold storage the coolant pipelines transporting glycol to the air coolers are made of plastics. The implementation process is much simpler (bonding) and easier than in the case of metal pipeline. Also, there is no problem of socalled oil traps associated with the transport of oil at long distances in refrigeration systems. However,

because of the occurrence of the additional heat exchanger (refrigerant/coolant) intermediate installation may be more energy consuming than direct expansion system due to the additional temperature difference.

Figure 6. Main screen of the control system of discussed cold store.

Figure 6. Main screen of the control system of discussed cold store.

Figure 7. Graphs of air temperatures, humidity of air and carrots temperatures in time.

Figure 7. Graphs of air temperatures, humidity of air and carrots temperatures in time.

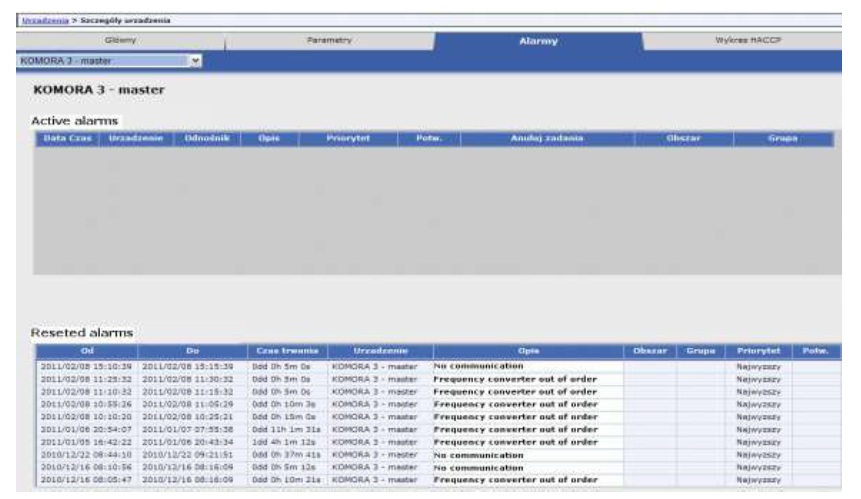

Figure 8. View on the exemplary alarms information provided by the control system.

Figure 8. View on the exemplary alarms information provided by the control system.

The special feature of the carrots cold storage is that the reduced heat load during winter and spring time.

During this period the glycol temperature raises together with temperature of evaporation. The evaporation temperature increases closely to the level of the temperature of evaporation in the direct refrigeration systems. During winter season when ambient air temperature is lower than temperature of the circulated

coolant. Under these conditions coolant can be cooled by ambient air in dry cooler, i.e. lamella fan heat exchanger. This solution named as free cooling causes decreasing of energy demands for cooling and

improves the economical efficiency of the system. Refrigeration system has been equipped with modern computer control system. This system allows not only efficient operation under precise control conditions but also visualization of operation along with recording of all important data. Operating parameters and additional information along with alarms are sent by GSM–telephone line and internet to an owner and maintenance company. Figures 6, 7 and 8 present some reports received by internet.

4. CONCLUSIONS

The experience collected during first season of store operation confirms the positive influence of high stability of temperature and humidity on storage conditions of carrots. High humidity of air protects vegetables from dehydration. The lack of condensation of water vapour on the stored carrots was confirmed.

Application of the indirect system reduced refrigerant charge in the system. Using superheat condensation for defrosting of air coolers has been evaluated. Application of plastic piping decreases costs, weight of pipelines, simplifies pipes connections and eliminates problems with corrosion. Computer control system assures continuous supervision and communication with an owner and maintenance company.

LITERATURE

Adamicki F., Czerko Z., 2002,. Storage of vegetables and potato (in Polish). PWRiL, Poznań.

Adamicki F., 2006, Methods of vegetables storage (in Polish), Hortpress, Warszawa.

Henze J., Hansen H.1988. Lagerräume fűr Obst und Geműse. Darmstadt, KTBL-Shrift 327:225

Weichmann J. 1987. Postharvest physiology of vegetables. Marcel Dekker Inc, New York.

Acknowledgement

This work was co-financed by the European Union within European Regional Development Fund, through

grant Innovative Economy UDA-POIG.01.03.01-20-137/09-00.